Rechampir brushes – the paintbrush for all those difficult to reach areas Some background information……

Traditional Brush Making

For hundreds of years, brushes were made by hand using very basic methods.

The traditional brush maker’s “shop” consisted of four pan hands who worked around a pan frame. This was a strong table with a central hole in which stood a charcoal stove. On this stove, stood a pan of hot, but never boiling pitch.

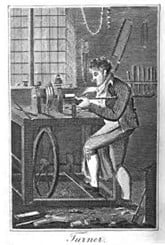

The stocks of the brushes were drilled to receive their bristles on a hand lathe worked by treadle. Every hole had to be hand-drilled at a slightly different angle.

The stocks were then held on the pan frame and the bristles held on a draw board. The pan hand then drew a bundle of bristles and parted them to prevent their natural curvature allowing them to bend too much in one direction. The root end was dipped in the pitch and tied with twine.

After a row of bristles had been inserted the wire was tied off so that they were held tight, and this was continued until the whole brush was “filled” with bristles

After all the bristles were inserted and the wire or twine secured a brush-back of thin veneer would be fixed over it to hide the work. These were glued with fish glue, but as this was also unreliable four small brass screws were also added to keep the back secure.

The brush was then “finished”- i.e. shaped, sanded, stained and polished. This could be a specialist job and some brushmakers described themselves as “brush finishers”.

The late 19th century and early 20th centuries saw the birth of the modern paint brush, with the advent of the use of rubber to set bristles inside a metal ferrule and to connect that ferrule to a handle using nails.